Showroom

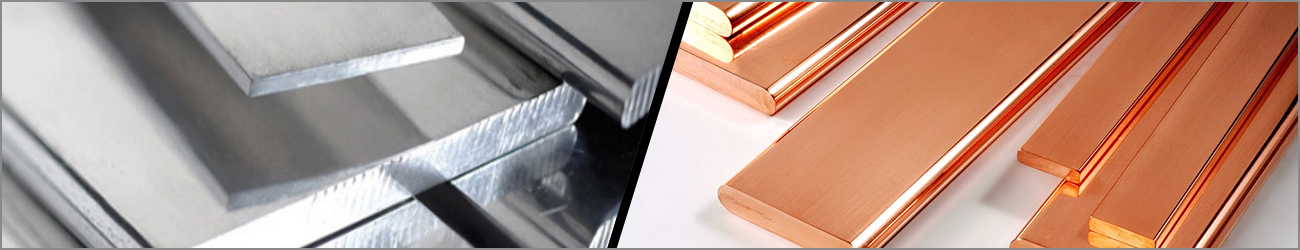

Aluminium products are designed for power grids, airplanes and electrical wiring in houses. These are attributed with mechanical and electrical properties. Our offerings are known for longer service life, maximum versatility and easy usage. Aluminium products are used for making window frames, cans, automobile, etc.

Brass products are resistant to corrosion and provide low friction. These are used in the making of hinges, ammunition, zippers, locks, electrical plugs, plumbing, sockets and more. Brass products have fine finishing, anti-corrosive nature and long-lasting service life.

Copper products find their application in kitchen sink, pull handles, door knobs, tools, railings, wires and musical instruments. These are integrated with anti-microbial and anti-corrosive properties. Copper products are also used for making jewelleries, table tops and other items.

Gunmetal products are best suitable for fabrication and engineering works. These are accustomed with features like heat resistance, robustness, longevity, high tensile strength and more. Gunmetal rods have a fine finishing and can be redeemed in different sizes, shapes and thickness.

Earth pit cover is employed for providing protection for various earthing terminations. It is light weighted and can be easily installed and maintained. Earth pit cover is efficient in diverting maximum current. Our offered product reduces ground resistance.

Metal wires are appreciated in industries for maximum efficiency, sturdiness and longer service life. These products find their usage in the manufacturing of hooks, textile machinery, baggage label clips, safety equipment and more. Metal wires are also ideal for electrical switchgear.

Lead product is utilized for caulking of joints in specialist batteries, gas mains, ceilings, walls etc. It has good ductility and ensures fast sealing and filling of little slots. Lead wool is available in different sizes of packaging.

G.I products have usage in commercial, residential and industrial applications. These are great for providing stable platform for sensitive equipment and operation. G.I products are made from top grade galvanized iron material and advanced technologies. Our offerings have maximum efficiency and reliability.