Aluminium Strip

269.00 - 279.00 INR/Kilograms

Product Details:

- Diameter Custom (if supplied in coil form)

- Usage & Applications Electrical, Construction, HVAC, Cable Wraps, Transformers, Automotive, Packaging

- Fabrication Process Rolling / Slitting / Cutting

- Outer Diameter Up to 1600 mm (Coil OD)

- Material Grade Pure Aluminium / Alloy as specified

- Corrosion Resistant Yes

- Features Flexible, Lightweight, Durable, Anti-Rust

- Click to View more

X

Aluminium Strip Price And Quantity

- 500 Kilograms

- 269.00 - 279.00 INR/Kilograms

- Negotiable (depends on size/thickness/width)

- Wooden pallet, protective wrapping, or as required

- Up to 35% (depending on temper)

- Customized, up to 3 tons per coil

- >60% IACS (for 1100 series)

- 2.70 g/cm³

- ASTM B209, EN573, JIS H4000, IS 737

- +/- 0.02 mm or as specified

- Mill Edge / Slit Edge

Aluminium Strip Product Specifications

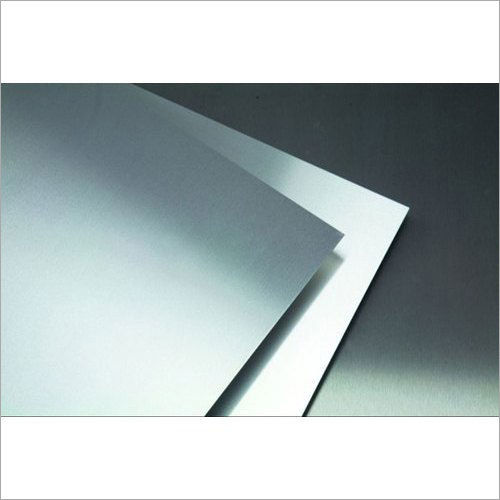

- Silver / Grey / As required

- 10 mm to 1250 mm

- Soft/Hard (O, H14, H18, H24, etc.)

- Customizable (Standard width: 10 mm - 1250 mm, Thickness: 0.15 mm - 6 mm)

- Mill Finish / Smooth Finish

- Mill Finish / Anodized / Coated

- Customizable (supplied in coils or straight lengths)

- According to Temper (Customizable)

- 1000/3000/8000 Series

- Up to 1600 mm (Coil OD)

- Rolling / Slitting / Cutting

- Aluminium Strip

- Strip

- Electrical, Construction, HVAC, Cable Wraps, Transformers, Automotive, Packaging

- Commercial Pure Aluminium / 1100, 3003, 8011, as per requirement

- High Tensile Strength

- Custom (if supplied in coil form)

- As per requirement (custom sizes available)

- Aluminium

- Flexible, Lightweight, Durable, Anti-Rust

- Custom as per order

- 0.15 mm to 6.0 mm

- Yes

- Pure Aluminium / Alloy as specified

- Negotiable (depends on size/thickness/width)

- Wooden pallet, protective wrapping, or as required

- Up to 35% (depending on temper)

- Customized, up to 3 tons per coil

- >60% IACS (for 1100 series)

- 2.70 g/cm³

- ASTM B209, EN573, JIS H4000, IS 737

- +/- 0.02 mm or as specified

- Mill Edge / Slit Edge

Aluminium Strip Trade Information

- 1000 Kilograms Per Week

- 1 Days

Product Description

aluminum stripis analuminumalloy with analuminumcontent of 99.5% or more.aluminum stripis made by slittingaluminumcoils.Aluminum striprefers tostripshape product which manufactured withaluminumas the main raw material, and mix other alloy elements.

Precision Engineering and Quality Standards

Aluminium strips are manufactured to strict standards including ASTM B209, EN573, JIS H4000, and IS 737. This ensures consistent quality, dimensional accuracy, and compliance for a diverse range of applications. Each batch undergoes careful inspection, guaranteeing +/- 0.02 mm tolerance and customizable hardness according to the required temper.

Versatile Applications and Customization

Our aluminium strips find application in electrical components, cable wraps, HVAC systems, transformers, automotive sectors, and construction. The product is available in mill finish, anodized, or coated surfaces, and a range of widths and thicknesses (from 0.15 mm to 6 mm), tailored to the clients preference for optimal performance in their specific use case.

Trusted Supply and Reliable Packaging

Supplied by leading distributors, manufacturers, and suppliers across India, aluminium strips are packaged securely on wooden pallets with protective wrapping. Coil weight and minimum order quantities are negotiable, ensuring flexibility for varying project scales and requirements.

FAQs of Aluminium Strip:

Q: How are aluminium strips manufactured to meet various industry standards?

A: Aluminium strips are produced using advanced rolling, slitting, and cutting processes, adhering strictly to standards such as ASTM B209, EN573, JIS H4000, and IS 737. This guarantees consistent quality and material properties suitable for multiple applications.Q: What customization options are available for dimensions and surface treatment?

A: Customers can specify the width (10 mm1250 mm), thickness (0.15 mm6 mm), coil weight, and outer diameterup to 1600 mm. Surface treatments include mill finish, smooth finish, anodized, or coated according to requirements.Q: Where are aluminium strips commonly used and what are their key benefits?

A: Aluminium strips are utilized in electrical systems, HVAC, cable wraps, transformers, construction, packaging, and automotive industries. Their flexible, lightweight, anti-rust, and high-conductivity features make them highly advantageous for these applications.Q: What is the process for ordering and packaging aluminium strips?

A: Orders are customizable with negotiable minimum quantities, depending on size, thickness, and width. Packaging options include wooden pallets, protective wrapping, or as needed, ensuring product safety during transport.Q: When should the selection of temper and grade be considered for aluminium strips?

A: Temper (O, H14, H18, H24, etc.) and grade (1100, 3003, 8011, etc.) should be selected during the ordering process, based on the intended application to ensure the required elongation, hardness, and tensile strength are met for optimal performance.Q: What edge types and tolerance levels can be specified for aluminium strips?

A: Edge types available are mill edge or slit edge, and tolerance can be customized as required, with a standard tolerance of +/- 0.02 mm provided to ensure dimensional accuracy for high-precision tasks.Q: How does the high conductivity of aluminium strips benefit electrical applications?

A: Aluminium strips, especially the 1100 series with conductivity above 60% IACS, provide efficient electrical transmission and are ideal for manufacturing components like cable wraps and transformer windings, ensuring reliable performance in electrical systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free