Brass Flat

560.00 - 570.00 INR/Kilograms

Product Details:

- Product Type brass

- Size 1.724kg-36.805kg

- Material brass

- Color goldenish brown

- Finish brass

- Application high speed machining like fasteners, gears, architectural extrusions, automotive engineering parts, etc.

- Usage high speed machining like fasteners, gears, architectural extrusions, automotive engineering parts, etc.

- Click to View more

X

Brass Flat Price And Quantity

- 100 Kilograms

- 560.00 - 570.00 INR/Kilograms

Brass Flat Product Specifications

- high speed machining like fasteners, gears, architectural extrusions, automotive engineering parts, etc.

- high speed machining like fasteners, gears, architectural extrusions, automotive engineering parts, etc.

- goldenish brown

- brass

- 1.724kg-36.805kg

- brass

- brass

Brass Flat Trade Information

- KOLKATA

- Cash Against Delivery (CAD), Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 500 Kilograms Per Day

- 1 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- STANDARD

- Sikkim, Meghalaya, Nagaland, Bihar, Mizoram, Andaman and Nicobar Islands, East India, Manipur, Assam, Odisha, Tripura, West Bengal, Jharkhand, Chhattisgarh

- ISO 9001-2015,MSME,IEC

Product Description

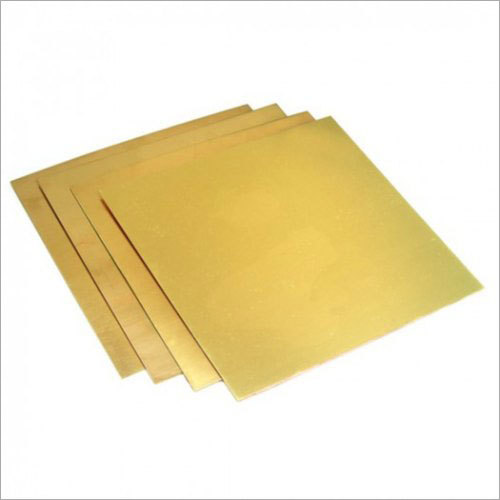

Brass bar is an ideal material for a wide range of applications. An alloy of copper and zinc, brass provides good durability, high corrosion resistance, and excellent aesthetics, all at a lower cost than comparable copper or bronze materials. Brass bar is easy to machine and otherwise fabricate, as needed.

Specification

| Country of Origin | Made in India |

| Alloy Or Not | Not |

| Brand | Shree Metal Industries |

| Finish Type | Polished |

| Material | Brass |

| Shape | Rectangle |

General Properties:

- Size - 356mm and 1418mm

- Thickness - 1 mm to 60mm

- Width - up to 160 mm

- Edge - Square Edge, Radius Edge, Full Radius Edge

- Weight - Per foot

- Standard & Material - AISI,ASTM,DIN,GB,JIS,EN

Available Sizes:

2 mm to 100 mm

| Minimum Thickness | Minimum Width | Maximum Width |

| 1.60 | 6.35 | 127.0 |

| Minimum Thickness | Minimum Width | Maximum Width |

| 50.80 | 76.20 | 127.0 |

Exceptional Performance for High-Speed Machining

The Brass Flat is engineered to withstand the demands of high-speed machining. Its goldenish brown finish and robust brass material ensure both functionality and visual distinction. Ideal for sectors like automotive, architectural, and precision engineering, this flat delivers reliable results across various advanced manufacturing processes.

Versatile Industrial and Architectural Uses

From gears to fasteners and architectural extrusions, our Brass Flat is suitable for a wide range of applications. Its unique properties make it a popular choice among manufacturers and engineers seeking both durability and smooth finishing in their end products.

FAQs of Brass Flat:

Q: How is the brass flat used in high-speed machining applications?

A: The brass flat is commonly used in high-speed machining to manufacture parts like fasteners, gears, and architectural extrusions. Its material properties allow for precise cutting and shaping while maintaining strength and structural integrity during intense machining processes.Q: What benefits does a goldenish brown brass flat provide to manufacturers?

A: The goldenish brown finish of the brass flat provides both aesthetic enhancement and protection against corrosion. This makes the finished products more visually appealing and increases their longevity in various industrial and architectural environments.Q: When should I choose brass flat over other materials for my project?

A: Brass flat should be selected when your project demands excellent machinability, durability, and an attractive finish. It is especially suitable for applications like automotive parts, architectural features, and fasteners where performance and appearance are critical.Q: Where are brass flats most commonly applied?

A: Brass flats are widely used in industries such as automotive engineering, construction, and architecture. They are ideal for fabricating gears, fasteners, and decorative architectural extrusions due to their strength and visual appeal.Q: What is the process for manufacturing brass flats in India?

A: Manufacturing brass flats involves high-quality brass casting, precise rolling, and controlled cooling, followed by surface finishing to achieve the characteristic goldenish brown appearance. Each step is closely monitored to ensure consistent quality and performance.Q: How does the size range of 1.724kg to 36.805kg benefit industrial buyers?

A: This wide size range allows buyers to select brass flats that align perfectly with their project requirements, optimizing material usage and reducing waste. It also enables customization for various applications, from small fasteners to large architectural elements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free